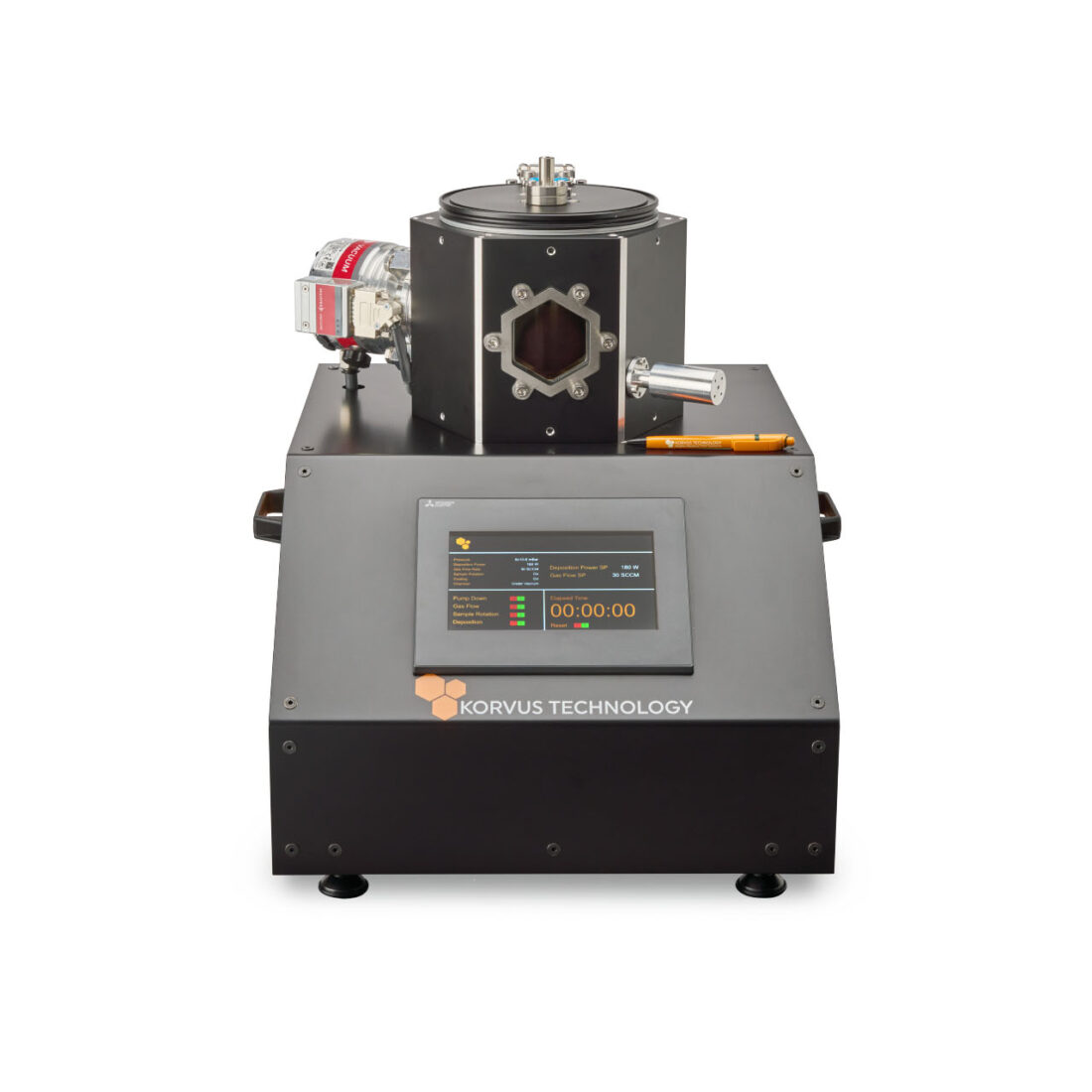

Benchtop and Compact Coating System

Korvus Technology offer two options for benchtop coating systems.

The HEX Mini, available in either DC sputtering or Thermal Evaporation models, or the HEX deposition system, a larger unit which is capable of accomodating up to three deposition sources and a QCM.

Expand Your Range of Deposition Capabilities

The HEX PVD coating system is lightweight and equipped with six modular aluminium panels, gas ports, and a full range of customisable source options. Regardless of their chosen applications, users can quickly reconfigure components on HEX systems without hassle.

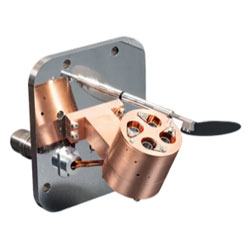

FISSION- Magnetron Sputtering Source

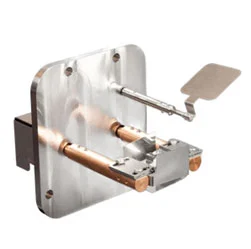

ORCA - Low Temperature Evaporation

TAU - Electron Beam Evaporation

TES - Thermal Boat Evaporation

FAQs About The HEX Benchtop PVD System

How Does Thin Film Deposition Work?

Thin film deposition is a process used to create very thin layers of material—ranging from a few nanometers to several micrometers thick—on a substrate surface. These films are essential in many technologies, including semiconductors, optics, solar cells, and sensors.

What Types of Coating Does The HEX System Support?

The bench-top HEX machine supports four primary ultrasonic coating techniques:

- Sputtering (including RF and DC magnetron sputtering)

- Thermal evaporation

- E-beam evaporation

- Organic evaporation.

An operator can use one or multiple techniques within a single process chamber, depending on their chosen applications.

What Are the Uses of Thin Film Coatings?

Thin film coatings are used to modify the properties of the surface material for a variety of applications. Learn about thin film applications.

What Makes the HEX Benchtop Coating System Unique?

The HEX system is a completely unique product due to its open frame architecture, allowing easy upgrades and modification. It can support multiple deposition sources in one chamber.

Contact Korvus Technology Ltd online to learn more about the benchtop HEX system.