Customisations

Seemless Integration of third-party instruments - An unrivalled ability to be customised

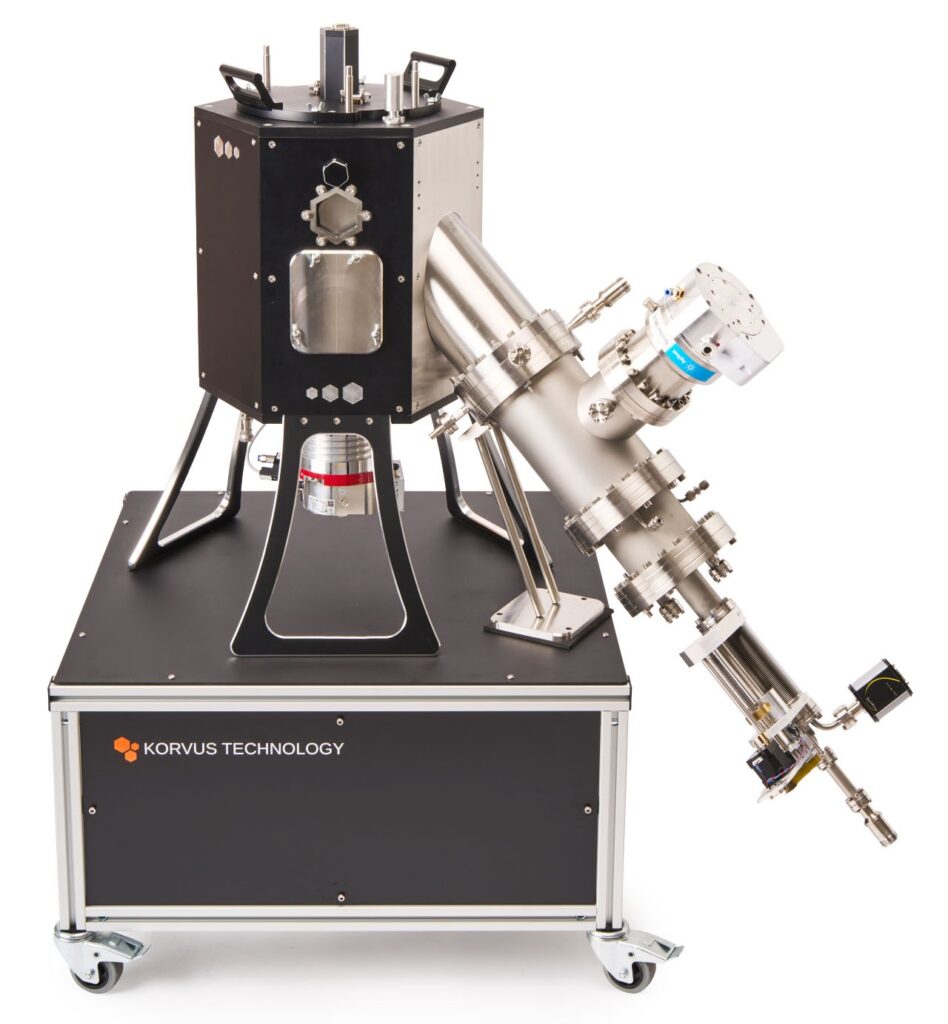

HEX series panels are easily changed, allowing for the modification of the vacuum chamber. This unique feature enables easy addition of any instrument after initial system purchase, eliminating costly design work, engineer visits, and system downtime.

The options available include:

- High Powered E-Beam

- Ion Gun

- Optical Monitoring

- Nanoparticle

- RGA

- Soft Sputtering

With its uniquely modular design, the HEX series offers the ability to integrate a range of third-party deposition and analytical techniques. This proveds unparalleled options for modification and enhancement. Even after purchase, customers can adjust their system to suit their research

Korvus is delighted to work in close partnership with two other UK companies, Theris Nanotechnology Ltd. and Plasma Quest Ltd.

Theris Nanotechnology is a manufacturer of nanoparticle sources that enable the creation of ultra-pure and size-selected nanoparticle films, as well as the generation of core-shell nanoparticles. This source is perfectly suited for research in an array of fields and gives new research insights that cannot be achieved with chemically-grown or self-assembled nanoparticles, including:

- Catalysis

- Energy storage

- Photovoltaic films

- Gas and liquid sensors

- Water splitting

Plasma Quest have developed a source technology that generates the plasma in a remote ICP source instead of at the magnetron target. The plasma is then directed toward the target via electromagnets, giving the unique ability to control the plasma ion density and ion energy independently. This has a number of benefits compared to regular magnetrons:

- Additional process space to deliver new coatings/properties

- Enables High Target Utilisation Sputtering (HiTUS®)

- Stable deposition for oxide and nitride thin films

- Deposition onto delicate substrates (low temp/damage deposition)

- Conformal coverage of uneven surfaces for a wide range of applications

- Less material wastage (full surface target erosion, no racetrack!)

- High deposition rate for ferromagnetic thin films and ability to create thick magnetic films

- Low stress control

- Excellent adhesion

Get in touch now to discuss the possibility of adding one of these novel manufacturing techniques to your modular PVD system.