PVD Coating Technology

PVD coating machines are widely used in many industries, including the aerospace, medical, and auto industries. Using physical vapour deposition and PVD coating machines, you can add functional and decorative coatings to automotive components, aeroplane blades, plastics, and much more. A high-tech coating system from Korvus Technology is an investment that will serve you for decades to come.

Has your business ever wanted to add new chemical, mechanical, or electrical properties to a source material, such as metal or ceramic? When you purchase a PVD coating machine, you can do exactly that.

During the PVD coating process, a compound material is vaporised and deposited onto a substrate in a vacuum chamber. Businesses can use PVD coating machines to apply coating and new properties to a batch of products or small parts quickly and easily.

Here’s a brief rundown of how PVD vacuum coating machines work:

- First, the PVD coating machine operator cleans the substrate with chemical or mechanical cleaning.

- The operator uses plasma etching or anodising to improve PVD coating adhesion.

- The PVD coating machine heats a source material until it evaporates. The evaporated material is then deposited on the substrate.

Key Features of Modern PVD Coating Equipment

High Vacuum Technology

After cleaning the substrate, it’s then placed in an airtight vacuum chamber. Operators then evacuate the chamber to encourage a low-pressure environment. This is necessary to remove gas molecules that might affect the coating process. The operator can then apply a coating in a perfectly even, thin layer.

Temperature Control Mechanisms

Many components, especially ultra-hard metals, require very high temperatures to vaporise. Advanced PVD coating machines come with temperature settings that you can fine-tune. For example, you can use thermal evaporation to heat a material to its boiling point, thus turning it into a vapour that’s ready for PVD coating.

Automation and Control Systems

Advanced automated features make it easier to manage your coating system. Today’s PVD coating machines come with automation technology that makes applying coating to a large batch a total breeze. Once you’ve set up and calibrated your PVD coating machine, it will handle every job with precision and impressive speed.

Applications Across Industries

Odds are good that PVD coating was used in the production of several pieces of equipment in your house, from cars to televisions.

PVD vacuum coating machines are used in many industries, including the medical, automotive, semiconductor, and aerospace industries.

Here’s how:

- Semiconductors: The semiconductor production industry uses PVD coatings to improve chemical resistance for delicate electronics. Without PVD coating, chemical erosion would wear components down well before they ought to.

- Automotive: PVD coatings safeguard combustion engines from friction and high temperatures. PVD coating improves the engine’s durability and fuel efficiency.

- Medical: When applied to metal medical tools, PVD coating prevents sticking and creates a bioincompatible surface.

- Decorative coatings: PVD coating machines are used in the production of decorative coats for jewellery, tools, and furniture handles. Operators can use a PVD coating machine to apply a metallic coat to plastic components for a luxurious look.

Advantages of PVD Coating

Improved durability: Thanks to PVD coating, the tools and equipment you produce will last longer, and that’s sure to put a smile on your customers’ faces.

Resistance to wear and corrosion: By altering the chemical or mechanical properties of equipment, tools, and components, you’ll improve the ability of your products to withstand corrosion and wear. PVD coatings are especially useful in the marine and auto industries.

Aesthetics: Want to add a shiny, eye-catching coat to your latest product? With a PVD coating machine, you can.

Eco-friendly: Today’s customers want to do business with a company that will support the environment. A PVD coating system doesn’t release harmful chemicals and toxins during the coating process.

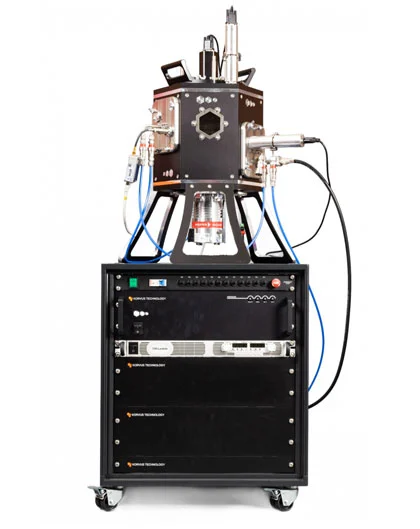

The Right HEX Series PVD Machine for Your Needs

Having trouble deciding between our HEX Series PVD coating machines for your production line? Below, we’ll take a look at each of our HEX Series systems, which include the HEX, the HEX-L, and the HEX-XL, to help you choose the right machine for your needs.

HEX: Standard Model for General Applications

Need a PVD coating machine with a small footprint? The standard HEX model is for you. This system has a 12-litre chamber capacity and a maximum sample size diameter of 4 inches (100 mm). It accepts up to three deposition sources.

HEX-L: Enhanced Model for Demanding Applications

The HEX-L PVD coating machine has a 50-litre chamber volume and accepts up to six deposition sources. The maximum sample size diameter is 6 inches (150 mm). This model offers more power for demanding tasks.

HEX-XL: Advanced Model for High-Volume Applications

The HEX-XL is the largest and most advanced of our PVD coating systems. This system has an 86-litre chamber volume, a 12-inch (300 mm) maximum sample size diameter, and accepts up to six deposition sources.

Additional Sources For Our HEX PVD System

The HEX-L system adapts to your needs. We have several deposition sources to customise the sources used in the system, including:

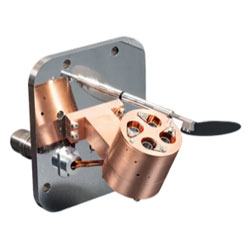

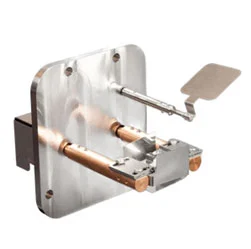

FISSION- Magnetron Sputtering Source

ORCA - Low Temperature Evaporation

TAU - Electron Beam Evaporation

TES - Thermal Boat Evaporation

Frequently Asked Questions

How Do I Know Which HEX Series Machine Is Right for My Needs?

To determine which PVD coating system to order, you’ll want to carefully consider a number of factors. This includes things like your components, source materials, and desired chamber volume and capacity. From there, you can determine whether you need a small or large coating system, among other concerns.

Are the HEX Series PVD Machines Easy To Maintain?

A HEX Series PVD coating machine is very easy to maintain. If you ever need help with your system or its components, we’re here for you. Our professionals can explain the process to help make your life easier.

Can the HEX Series Machines Handle Multiple Types of Coatings?

Your HEX Series PVD coating system can handle a variety of coatings, including metals and organic materials. The flexibility of these machines is what makes them so beneficial for a variety of applications.

Are There Any Environmental Benefits To Using HEX Series PVD Machines?

Yes, the PVD coating machine comes with some notable environmental benefits. A PVD coating machine won’t release harmful chemicals into the air during the deposition process, thus, these systems are safe for the environment. By choosing to use one, you can lower your carbon footprint.