Thin Film Batteries

Thin Film Battery Construction

Battery research is a key area for many areas of today’s academia, with the hope that we can produce batteries at increasing low-costs and sizes, longer lifetimes, but while keeping their environmental impact to a minimum. One of these avenues for battery research is the production of thin-film lithium-ion batteries.

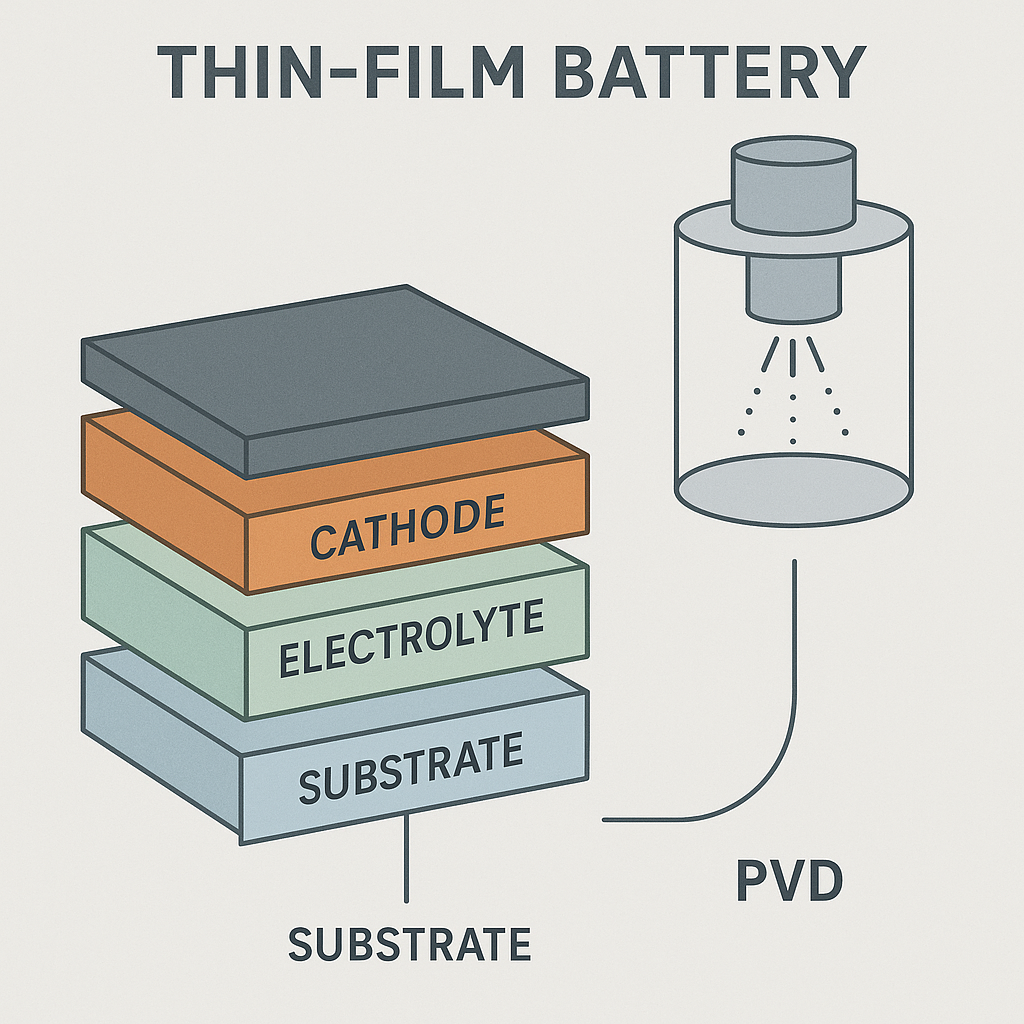

This particular solid-state battery has a much lower manufacturing cost but still maintains the benefits that solid-state batteries can bring. In order to fabricate one of these batteries, PVD may be used to deposit a thin film of cathode material onto the current collector – this is usually done via magnetron sputtering of a lithium polymer. An electrolyte must then be deposited followed by lithium to act as the anode.

The full fabrication process requires multiple layers of varying materials to be sequentially deposited without exposing the cell to air. At Korvus Technology, we have developed a cluster system that allows for sequential deposition runs without the need to break vacuum or contaminate your chambers with multiple materials. A single chamber can be used for the low-temperature thermal evaporation of lithium, then an automatic transfer of the sample will move it into a separate chamber for the ceramic sputtering of lithium polymers.

This process can be done fully automated and all done under the protective inert atmosphere of a glovebox to avoid any contamination that could affect the efficiency of the fabricated battery.

If a single deposition chamber or modular cluster system, optimised for battery fabrication, is of interest, or you just want to know a little more, please feel free to reach out – sales@korvustech.com.

Thin Film Battery FAQs

What is a thin film battery?

A thin film battery is a type of solid-state battery that uses thin layers (typically micrometres or even nanometres thick) of materials to store and deliver electrical energy. These batteries are designed with deposited thin films of electrode and electrolyte materials on a substrate, often using methods like Physical Vapour Deposition (PVD) or Chemical Vapour Deposition (CVD).

They’re compact, lightweight, and can be integrated into microelectronic devices, wearables, medical implants, smart cards, and Internet of Things (IoT) devices.

How are thin film batteries made using PVD?

Thin film batteries made using Physical Vapour Deposition (PVD) are fabricated by sequentially depositing each functional layer—electrodes, solid electrolyte, and current collectors—onto a substrate in a vacuum environment. This allows for precise control over the thickness, composition, and structure of each layer, which is critical for performance in micro-scale applications.

What methods of deposition are used?

Thin film batteries are fabricated using vacuum-based deposition techniques, such as:

Sputtering

Thermal evaporation

Electron beam evaporation

Pulsed laser deposition (PLD)

These methods allow precise control of film thickness, composition, and layer uniformity.

Where are thin film batteries used?

Uses of thin film batteries include: Medical implants (e.g., pacemakers, neural interfaces), wearables and smart sensors, MEMS devices (Micro-Electro-Mechanical Systems), RFID tags, Backup power for microelectronics and Solar-powered IoT nodes.

What are the advantages and disadvantages of thin film batteries?

Advantages

Small size & light weight – Ideal for micro-devices and integrated electronics.

Long cycle life – Can endure thousands of charge/discharge cycles.

Solid-state design – No flammable liquid electrolytes, making them safer.

Flexible integration – Can be deposited directly onto chips or flexible substrates.

Fast charge/discharge – Thin layers allow quick ion movement.

Disadvantages

Low energy capacity – Small size = less total energy storage.

Complex manufacturing – Requires cleanroom and vacuum deposition equipment.

Expensive materials and processes – Not yet cost-effective for high-energy applications.