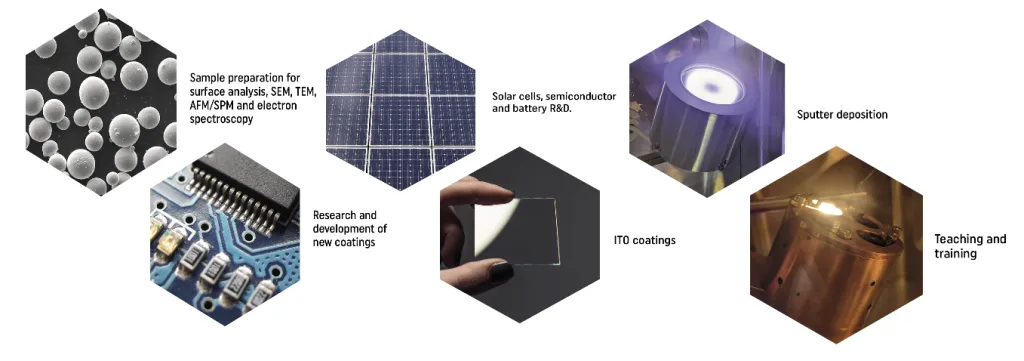

Applications

System Applications

Due to the versatility and flexibility of the HEX series, the systems are ideal for many research and training applications. The modular design allows the system to be reconfigured in minutes and ensures that it can be used for a variety of deposition applications with minimum effort. Thin film deposition has a range of applications in various fields; keep up-to-date with our articles, where you can explore the uses in depth, such as thin-film batteries and solar cells.

Some of the thin-film system options are listed below. If you have any specific requirements, please get in touch with us, and we will be happy to design a configuration to suit your needs.

The extensive range of deposition sources, sample stages and accessories in the HEX range, including single and four-pocket electron beam evaporators, low-temperature organic evaporators, RF and DC sputtering sources (including HiPIMS) and in-situ measurement options, ensures that the HEX series can provide solutions for a wide variety of coating and research applications.

Thin Film Training

The HEX series has been developed with student training in mind. Its modular construction allows various key elements to be exposed, discussed and interacted with, enabling student laboratories to fully explore the mechanical, material and growth elements of thin film research and nanomaterials.

The HEX’s ability to be quickly reconfigured at low additional expense allows the system to provide simple thin film training on a reproducible and recognisable platform for various deposition/coating techniques ranging from sample preparation for surface analysis to e-beam, sputtering, thermal, organics (for OLED research) and a range of other thin film deposition techniques.

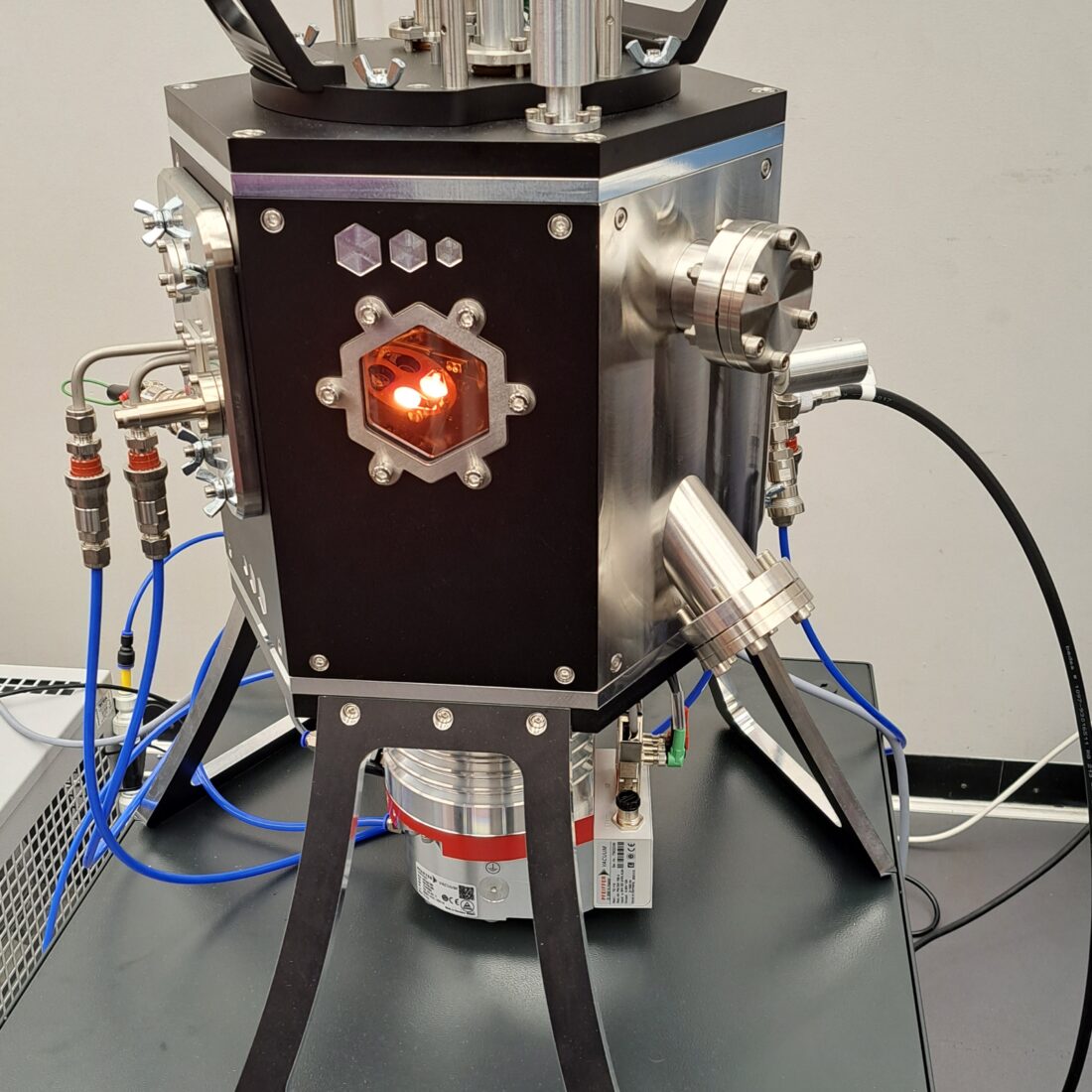

All connectors/fixings on the system and the sources, including gas and water flow, are quick connects, allowing for the elimination of most tools during system operation and sample/target changes. The HEX system’s compact footprint and the option to have it either bench, rack, or frame mounted make it an ideal size for any teaching environment and enable simple transfer to other laboratories/departments where necessary.

Customisations

One of the main benefits of the HEX Series is the freedom it gives users to customise and add third-party components to their chamber. With conventional PVD systems, the single-piece metal vacuum chamber prohibits the retrofitting of new ports and flanges. Once you purchase a conventional chamber, it is fixed in that state.

With the HEX Series, the detachable side panels mean that the architecture of the chamber can be changed at any time. Panels with customised flange ports with customised positions can easily be added by researchers.

Korvus has allowed researchers to attach CF flange ports to a HEX system for vacuum suitcase transfer (left) and facilitated the addition of in-situ ellipsometry, microwave plasma sources, ion guns, residual gas analysers (RGA) and many other customisations to our HEX Series systems.

Frequently Asked Questions

Whats the difference between HV and UHV?

HV (High-Vacuum) deposition systems refer to vacuum systems that, when fully evacuated, can reach base pressures of down to E-8 mbar. This is typically accomplished using both roughing and turbomolecular pumps and can often require several hours or even overnight pump-downs to achieve the required pressures.

UHV (Ultra-High-Vacuum) refers to systems that reach far below E-8 mbar and usually down to E-10 mbar base pressure range and below. This is achieved through the use of roughing, turbo, and cryogenic/ion pumps, along with bake-outs, which can take several days or even weeks to reach the desired pressure. UHV systems provide an unrivalled level of purity and are essential for many processes such as satellite and other space component testing, MBE deposition and other research needs.

Both systems require technical expertise to build and operate, but HV systems can give a level of modularity and flexibility (along with a much lower cost) that UHV systems cannot.

What Is a PVD System?

A PVD system is a machine designed to create thin-film coatings on a variety of materials. Operating within a vacuum chamber, it vaporises solid materials and deposits them, atom by atom, onto a substrate. This precise deposition process produces highly durable coatings, with meticulous control over thickness and composition.

The PVD process involves several stages: evaporation, transportation, condensation and bonding. There are many methods of PVD coating with their own use cases that you can read about on our website. Thermal evaporation, for example, uses high temperatures to vaporise the target material. Alternatively, sputtering employs ionised gas to bombard a target, dislodging atoms for deposition. Thermal evaporation offers higher throughput, while sputtering provides exceptional uniformity and minimal impurity levels.

PVD systems are capable of coating a wide range of materials, including metals, wafers and glasses. They are widely used in industries requiring robust and durable coatings for applications in the medical, aerospace and solar industries. The vacuum environment ensures purity and strong adhesion, resulting in long-lasting, high-performance coatings.

What Are The Uses of PVD Coating?

Creating thin films with PVD coating allows manufacturers to change or enhance the properties of the substrate. The evaporated material is deposited onto the substrate in a controlled process, providing additional durability or conferring new properties such as conductivity, resistivity, or transparency.

What Are The Advantages of Using Physical Vapour Deposition Systems?

PVD systems provide precise and durable coatings for a wide range of applications. PVD is used due to the coatings’ adhesion, durability and resistance to wear.

Advantages include:

- Versatility: Coatings can be vaporised in a vacuum and deposited atom by atom, allowing for precise multilayer films.

- Efficient processes: The techniques ensure uniform coatings by precisely controlling the deposition of atoms or molecules, reducing waste and enhancing efficiency, even for complex substrates.

- Enhanced properties: The use of oxygen and other reactive gases enables compound materials (e.g., titanium nitride) for corrosion resistance and reduced friction.

- Environmentally friendly: PVD produces functional and protective coatings with no toxic residues.

What Makes the HEX Series Unique?

Many bench-top thin film deposition systems are solid-state instruments that offer limited functionality. The HEX series is unique amongst thin film deposition systems due to its versatility — its modular design allows for customisation and robust user control features. Not only does this make the HEX ideal for teaching about various thin film techniques, but it also allows research and production facilities to incorporate the latest advancements in thin films into their bench-top system.

Please contact us at Korvus Technology or download our brochure here for more information.