Sputtering Machine

Korvus Technology’s proprietary HEX series of compact, thin-film deposition systems offers a wide range of deposition solutions for varied research and development needs.

Each HEX system features a hexagonal, aluminium-framed high-vacuum chamber. These six-sided structures are lightweight yet sufficiently sturdy for most physical vapour deposition methods. All HEX systems support six modular panels, including:

- Blank panel

- Viewport panel

- Deposition source panel

- QCM panel for in-situ monitoring

- PLD instrument process control panel, including mass flow and thickness controls

You can start with the base model, which features an 80 l/s pump and a multi-sample holder and supports base vacuums up to 8×10-7 mbar and sample sizes up to 100 mm.

You can also upgrade to more advanced options, including a 300 l/s pump supporting a base vacuum of 4×10-7 mbar and a HEX-L chamber accommodating sample sizes up to 150 mm. All upgrades are designed for easy installation to minimise downtime and installation costs.

Supporting a Range of Techniques and Applications

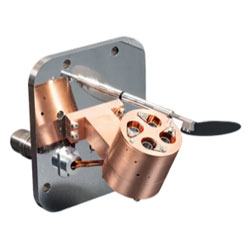

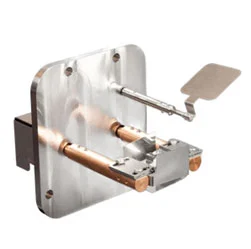

With the HEX system’s flagship Fission series of magnetron sputtering equipment, you can switch effortlessly between RF and DC sputtering without special tools or long downtimes.

The fission system supports the sputtering of all:

- Solid metals

- Magnetic materials

- Insulators

- Semiconductors

You can even process multiple sources to grow a composite thin film.

The magnetron sputter deposition system features quick-release cooling and water connectors for a quick and simple set-up and accommodates reactive sputtering through the introduction of reactive gas via a separate feed or directly into the vacuum environment.

The HEX Fission module also supports high-power impulse magnetron sputtering (HiPIMS), in which sputtered particles land on the target surface as energetic ions instead of neutral atoms.

Looking for solutions for other applications? The HEX series supports a wide range of sputtering deposition methods, including thermal evaporation and electron beam evaporation.

Learn more about the TAU e-beam evaporation system and the TES thermal evaporation system.

Sputter Deposition Systems

The HEX thin film deposition system supports multiple applications of thin-film deposition, including:

- Resistor applications

- Optical thin films

- Polymer applications

- Battery applications

- Solar cells applications

- Interference applications

- Zinc oxide-based applications

- Magnetic applications, including DC magnetron sputtering

To learn more about the physical sputtering process and the HEX system — including thin-film deposition, DC sputtering, and magnetron sputtering — read our articles about PVD coating, PVD vs CVD, and magnetron sputtering.

Customise With Sources

Most thin film deposition systems have limited functionality. The HEX-L system adapts to your needs. We have several deposition sources to customise the sources used in the system, including:

FISSION- Magnetron Sputtering Source

ORCA - Low Temperature Evaporation

TAU - Electron Beam Evaporation

TES - Thermal Boat Evaporation

Our Sputtering Systems

What Is Sputtering?

Sputtering is one of the most popular methods of thin film deposition. It is a coating process in which a target surface receives a thin film of accelerated or “sputtered” atoms. The source or target material of the sputter coating can be a pure metal, an alloy, or a compound, such as an oxide or nitride.

How Does a Sputtering Machine Work?

Sputter deposition involves the bombardment of the target material with high-kinetic-energy ions in an inert-gas-filled vacuum chamber. This causes the target material to sputter a fine vapour of atomic particles, which travels through the gaseous plasma and lands on the sputtering target as a thin film. Watch our video of sputtering explained.

Is the HEX a Magnetron Sputtering System?

Yes, the HEX series supports magnetron sputtering sources. Our modular system creates a magnetic field to trap electrons, inert gas atoms, and gas flow discharge over the source material, which enables faster deposition rates and a greater sputter yield. Learn more about magnetron sputtering.

What Makes the HEX Sputtering System Unique?

The HEX series is a surface and coatings technology that combines high performance with cost-effective and easy-to-use modular components. Unlike other solutions on the market, our system enables you to switch between DC and RF sputtering without specialised tools or lengthy downtime.

Does the HEX Support DC Sputtering and RF Sputtering?

Yes, the HEX’s fission source enables users to choose between an alternating current and direct current, depending on their needs.